sudarsan engineering

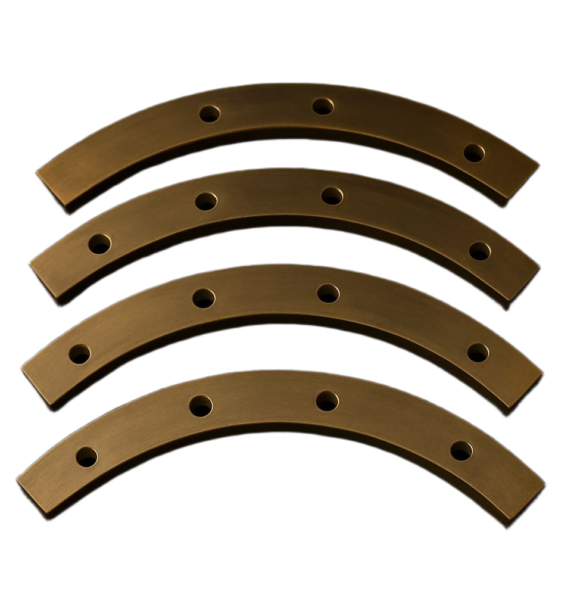

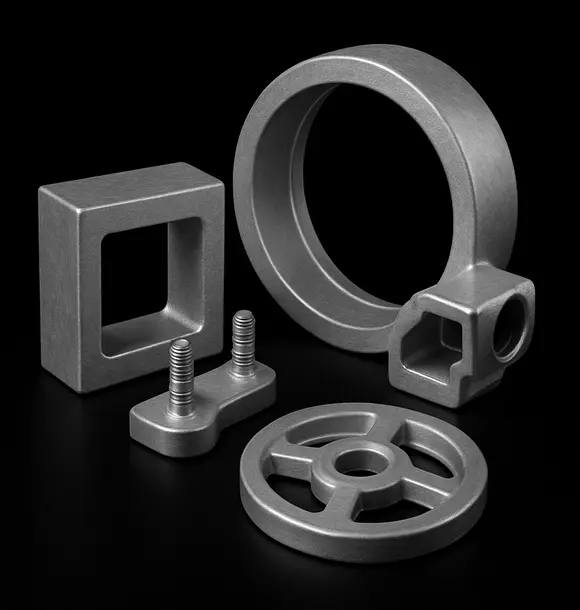

Manufacturer of FERROUS NON- FERROUS ALLOY CASTINGS

About Engineering

Sudarsan Engineering

Sudarsan Engineering Industries (SEI) is an ISO-certified company established in 1972. With over 50+ years of experience, SEI has built a strong reputation as a leading manufacturer of ferrous and non-ferrous alloy castings and precision-machined components. Our expertise lies in developing critical components and reverse-engineering parts even in the absence of technical drawings or dimensions. What sets us apart is our deep knowledge of alloy compositions and characteristics, which enables us to deliver high-performance, customized solutions for a wide range of industries such as pumps, defense, oil & gas, automotive, hydraulics, cement, and thermal power plants.

For over a decade, our clients have trusted us for our superior quality standards, reliability, precision, timely deliveries, and responsive customer service.

Read More

Our manufacturing capabilities are rooted in advanced sand casting and gravity die casting techniques, supported by a fully integrated in-house foundry and machine shop. This setup allows us to create intricate shapes and achieve high levels of machining accuracy. We produce components ranging from 0.1 kg to 300 kg per piece, precisely tailored to meet specific customer requirements. To ensure consistent alloy quality, we perform pre- and post-pour chemical analysis using a spectrometer and offer third-party witnessing for metal pouring and testing processes. Additionally, our ability to formulate custom alloys in-house further enhances our ability to meet unique client demands. With decades of expertise, specialized focus on aluminum and copper-based non-ferrous alloys, and a commitment to delivering end-to-end casting and machining solutions, SEI continues to be a trusted partner for leading industries across the globe. At Sudarsan Engineering Industries, we are driven by a singular focus: delivering excellence through quality, precision, and durability in every component we manufacture.

Facilities at Sudarsan Engineering Industries

At SEI, we are equipped with infrastructure to support complete in-house manufacturing, from alloy preparation to final machining. Our setup

ensures high precision, fast turnaround, and uncompromised quality.

Factory & Infrastructure

- Factory Shed spanning 5,600 sq. ft. for streamlined production

- Integrated Foundry & Machine Shop under one roof for seamless operations

- In-house Master Alloy Storage Area to ensure material consistency and readiness

Quality & Testing

- Spectrometer-based chemical analysis

- Dimensional inspections

- Third-party witnessing and validations

Machining Capabilities

- All-axis Machining

- Vertical Milling Machines

- Turning & Drilling Machines

- High-precision setups for complex geometries and close tolerances

Prototyping & Moulding

- 3D-Printed Patterns & Moulds for sand casting

- Rapid prototyping for new product development

- Cost-effective tooling solutions for complex designs

Years of experience in foundry & machine shop

Alloys

New developments

Staff

Why Choose SEI?

At Sudarsan Engineering Industries, we combine deep industry experience with technical excellence to deliver superior solutions. Here’s why leading industries around the world choose us: bine deep industry experience with technical excellence to deliver superior solutions. Here’s why leading industries around the world choose us:

-

50+ Years of Manufacturing Expertise

Established in 1972, we bring over five decades of experience in casting and precision machining. -

Experts in Non-Ferrous Alloys

Specialized in Aluminum and Copper-based alloys, we understand complex metallurgical behaviors and tailor materials to performance needs. -

Complete In-House Manufacturing

From raw alloy preparation to final machining, all processes are executed under one roof—ensuring quality control and production efficiency. -

Critical Component Specialists

We excel in reverse engineering, even without drawings or dimensions, to recreate high-performance components for demanding applications. -

Proven Across Industries

Trusted by clients in defense, oil & gas, pumps, automotive, cement, power, and hydraulics, we deliver consistently reliable results. -

Precision, Quality, and On-Time Delivery

Our customers rely on us for tight tolerances, rigorous quality testing, and strict adherence to delivery schedules. -

Modern Tools & Technologies

With facilities like 3D-printed moulds, spectrometer-based alloy analysis, and multi-axis machining, we stay at the forefront of manufacturing innovation.